l

l

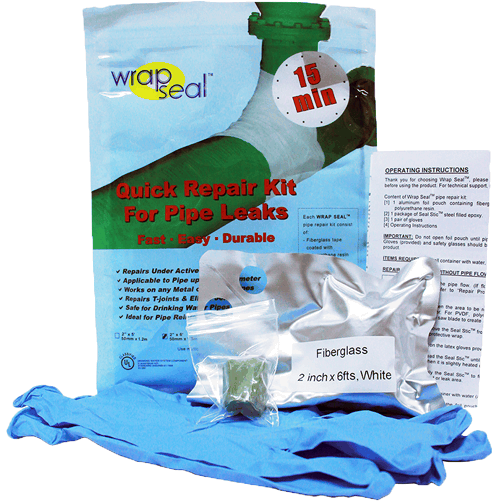

Steel Copper Aluminium Galvanized steel PVC CPVC

Stainless steel Polyethylene Polypropylene Cast-iron Concrete FRP/GRE

Building & amp; Facilities

Building & amp; Facilities Electronics

Electronics Industrial Processing

Industrial Processing Irrigation

Irrigation Oil & amp; Gas

Oil & amp; Gas Chemical

Chemical Manufacturing Plants

Manufacturing Plants Marine

Marine Military

Military Offshore

Offshore Food Processing

Food Processing Petrochemical

Petrochemical Pharmaceutical

Pharmaceutical Power Generation

Power Generation Pulp & amp; Paper

Pulp & amp; Paper Wastewater

Wastewater Water Distribution

Water Distribution| Pressure tested | : | 1/2″ (15 mm) steel pipe with 1/8″ (3 mm) hole when repaired with Wrap Seal withstands 4000 psi (281 kg/cm2) |

| 1/2″ (15 mm) steel pipe with 1/2″ (13 mm) hole when repaired with Wrap Seal withstands 600 psi (42 kg/cm2) | ||

| Tensile strength | : | 3920 psi (276 kg/cm2) |

| Bond strength | : | 230 psi (16 kg/cm2) |

| Tensile elongation | : | 1.2 % ± 0.7 % |

| Compressive strength | : | 13750 ± 530 psi (967 ± 37 kg/cm2) |

| Yield strength | : | 2260 psi (159 kg/cm2) |

| Cured hardness | : | 82 Shore D |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| ½” (15mm) | 1 A | 1 A | 1 A |

| ¾” (20mm) | 1 A | 1 A | 1 A |

| 1″ (25mm) | 1 A | 1 A | 2 A |

| 1¼” (32mm) | 1 A | 2 A | 3 A |

| 1½” (40mm) | 2 A | 2 A | 1 B |

| 2″ (50mm) | 1 B | 1 B | 1 B |

| 2½” (65mm) | 1 B | 1 B | 2 C |

| 3″ (80mm) | 1 B | 2 C | 2 C |

| 4″ (100mm) | 1 B | 2 C | 3 C |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| 5″ (125mm) | 2 C | 2 C | 3 C |

| 6″ (150mm) | 2 C | 2 C | 4 C |

| 8″ (200mm) | 2 C | 3 C | 5 C |

| 10″ (250mm) | 3 C | 4 C | 6 C |

| 12″ (300mm) | 4 C | 5 C | 8 C |

| 14″ (350mm) | 4 C | 6 C | 8 C |

| 16″ (400mm) | 5 C | 7 C | 9 C |

| 18″ (450mm) | 5 C | 8 C | 9 C |

| > 18″ (450mm) | Contact SealXpert for recommendations | ||

| Roll size | A (2″ x 5′) (50mm x 1.2m) | A (2″ x 6′) (50mm x 1.8m) | B (2″ x 12′) (50mm x 3.6m) | B (3″ x 9′) (75mm x 2.7m) | C (4″ x 12′) (100mm x 3.6m) |

Stop the pipe flow

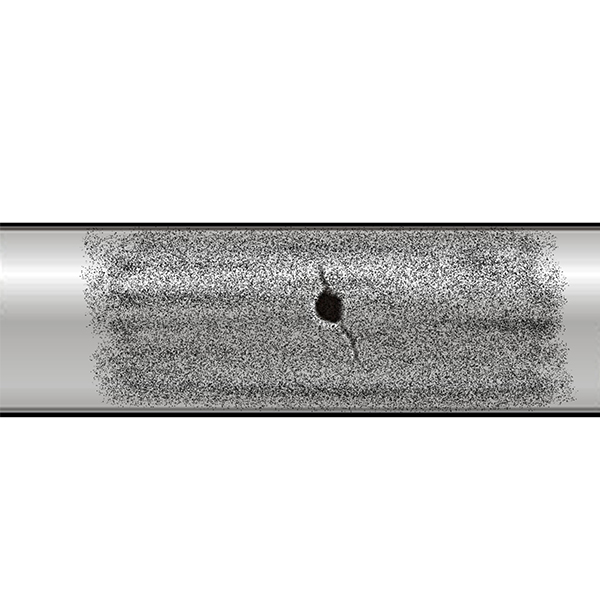

Stop the pipe flow Roughen the area to be repaired

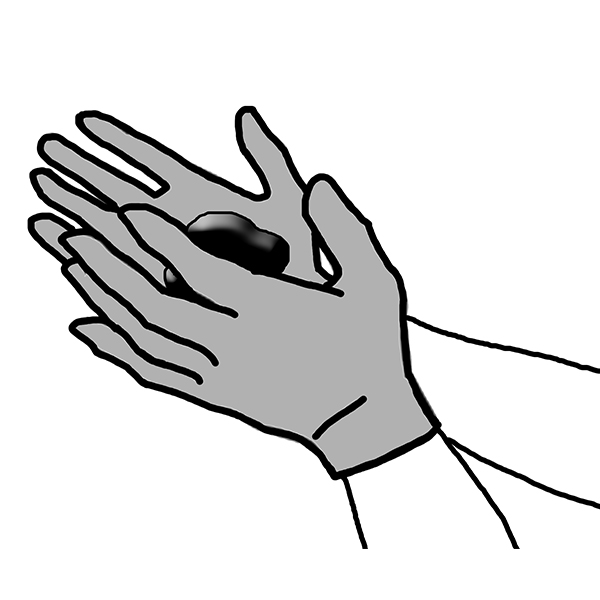

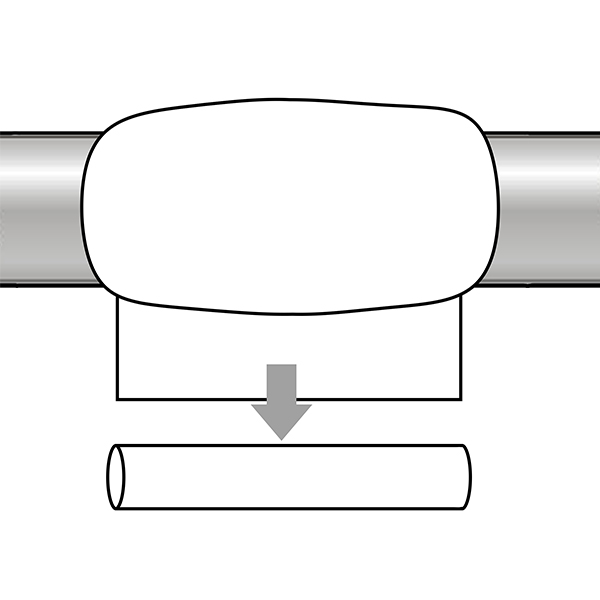

Roughen the area to be repaired Knead the Seal Stic

Knead the Seal Stic Apply the Seal Stic to fill in holes or crack of the damaged or leak area.

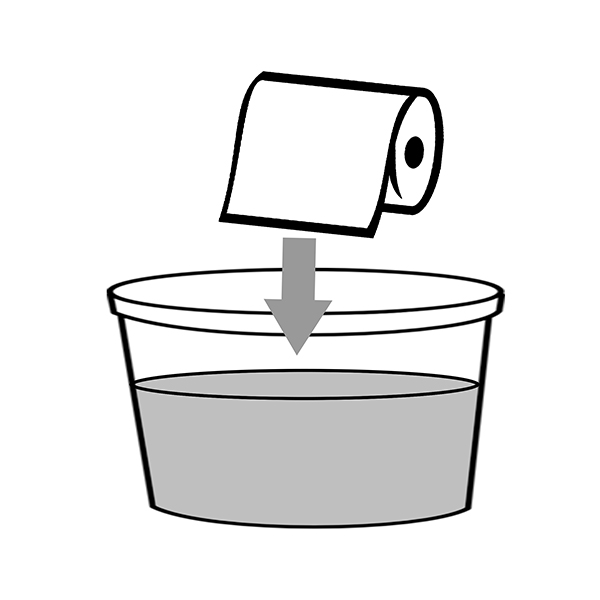

Apply the Seal Stic to fill in holes or crack of the damaged or leak area. Immerse the Wrap Seal Fiberglass Tape into water

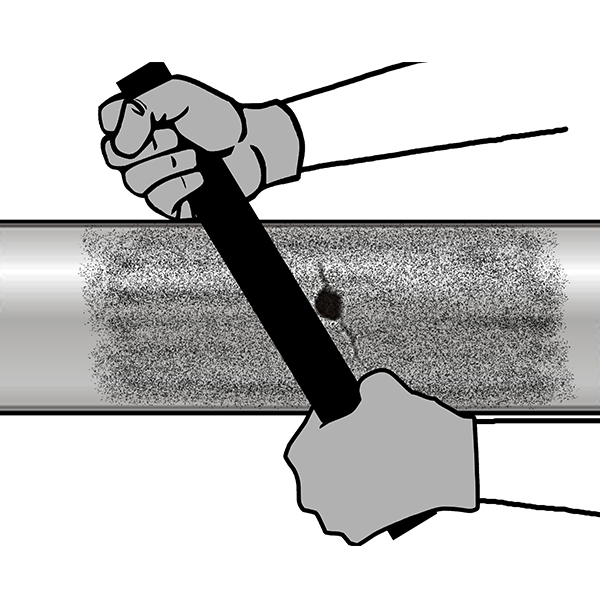

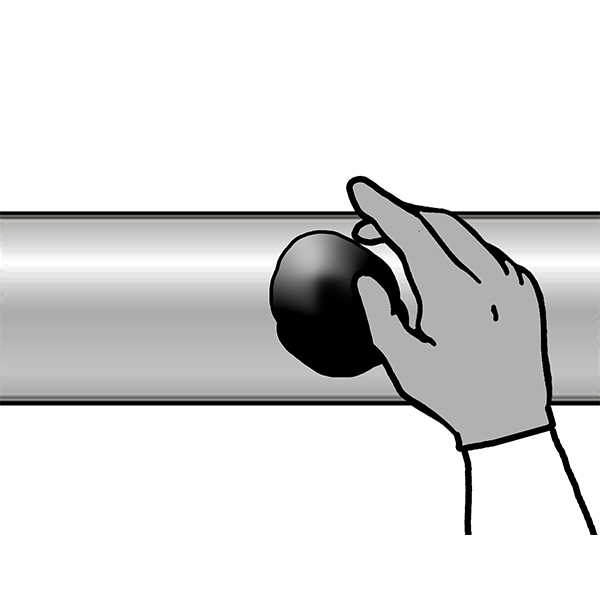

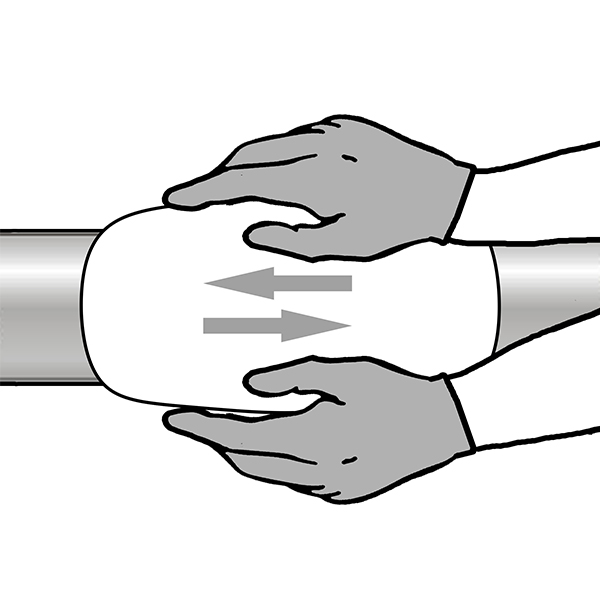

Immerse the Wrap Seal Fiberglass Tape into water Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll Discard the plastic tube at the end of the roll

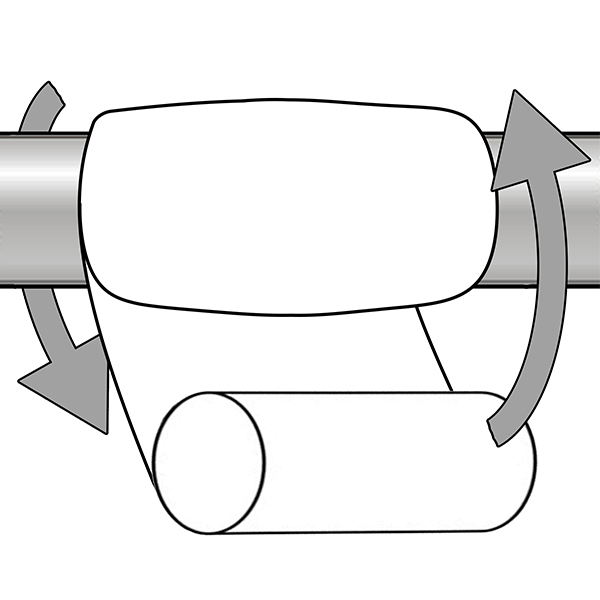

Discard the plastic tube at the end of the roll Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap

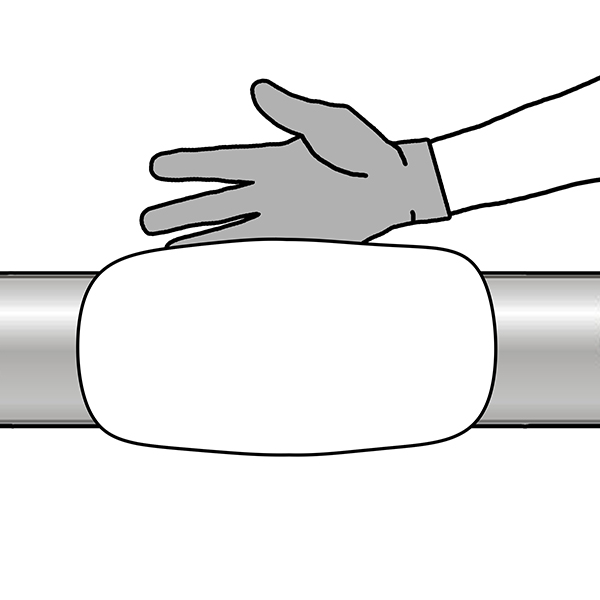

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance